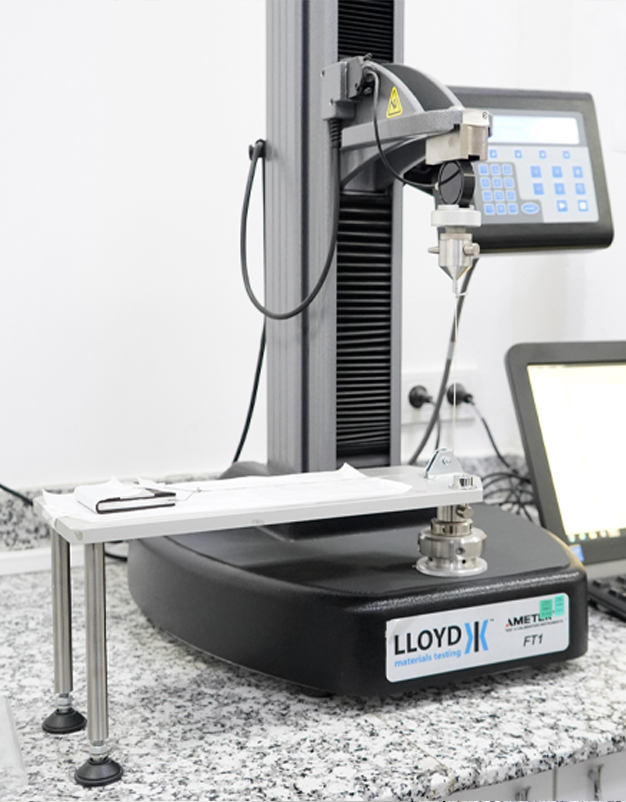

The strength and elongation of PE films are determined. Our company performs its tests according to ASTM D 882 Test Standard.

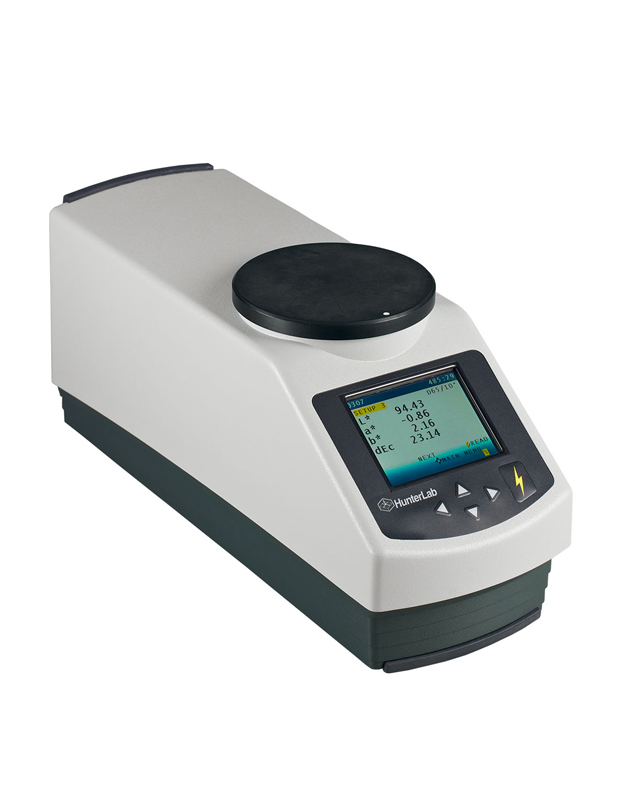

Sunpet Ambalaj has 3 laboratories in its organization. Our laboratories are organized according to the needs of the production sites they are located. Our production inputs and products are subjected to tests and controls according to certain criteria by experienced chemists and engineers in our laboratories.

QUALITY DOCUMENTS

OUR QUALITY POLICY

Our aims, Our purposes:

The organization has adopted as its purpose to provide services in accordance with legal requirements, based on customer demands and expectations, and committed to the principles of continuous development and improvement.

To achieve superior competitive strength, the foundation of our development lies in producing preforms and flexible packaging products in the packaging industry with advanced technology, environmentally and health-conscious, and in compliance with food safety standards.

Food Safety and Customer Satisfaction are the key to achieving our goals in production and services.

For the Integrated Management System, the establishment and maintenance of the philosophy of continuous improvement, where the participation and competence of all employees are ensured, and quality and food safety are everyone's responsibility, is an indispensable part of our company's philosophy.

Safe products and our quality are our future, we care about our future.

©2012 Sunpet Packaging all rights are reserved.